Interview with Alberto Maestre, CEO of Técnica de Fluidos

With more than 40 years of experience, Técnica de Fluidos has established itself as a benchmark in the supply and installation of pumping equipment and industrial instrumentation systems. The company offers advanced technological solutions for sectors such as water treatment, food, cosmetics or the pharmaceutical industry. In 2026 it will be a Premium Partner of Expoquimia, an event with which it fully shares values such as innovation, sustainability and efficiency.

What do you consider to be the main factors that have driven Técnica de Fluidos leadership in the market?

TDF has the most complete and recognized range of pumps, filters and accessories that exist on the market, and also has a team of expert professionals who have specialized for decades in the control and pumping of fluids. All this, together with an unrivalled service, our own warehouses in the main industrial regions with stock of pumps, spare parts and accessories, and the ability to offer complete systems and tailor-made solutions to our industrial customers in Spain, Europe and America.

Today, TDF is the only Spanish company in the industrial pump sector that, in addition to leading the national market, also has a strong presence in 14 international subsidiaries, which gives it a leading position in the main countries of Europe and South America.

How do you manage technological innovation to stay ahead of the curve in such a diverse and demanding sector?

For years we have had a team of engineers in Spain, who work on the design and development of complete custom pumping systems, as well as on innovative solutions adapted to the needs of the industry.

This technical team has been reinforced in recent years with an additional team of engineers active in our facilities in Buenos Aires.

Its equipment is present in sectors as diverse as water treatment, the food industry or pharmaceuticals. What approach do you follow to tailor your solutions to the specific needs of each industry?

TDF has specialists with decades of experience in the pharmaceutical, biotech, food, chemical and petrochemical markets. This is in addition to the long experience of our suppliers and partners, who are world leaders, and with whom we work very closely in Europe and South America.

What advances is Técnica de Fluidos developing to offer more environmentally friendly equipment with lower energy consumption?

TDF has been implementing its own sustainability plan for years, which includes measures such as the installation of solar panels in several of our buildings. In addition, the company’s car fleet is gradually electrifying and we have opted for rainwater reuse systems. In the future, we are considering increasing our initiatives in this area.

On the other hand, TDF has in its catalogue Wilden’s range of Pro-Flo® SHIFT pneumatic pumps, the most efficient on the market, which achieve savings of up to 60% in air consumption compared to other manufacturers of this type of pump. This line has won numerous awards and the energy savings it achieves are amazing.

Likewise, we have already incorporated the latest generation motors into our ranges of electric pumps, which also achieve significant savings.

In addition to manufacturing and distribution, the company offers installation, maintenance and technical advice. How important is this comprehensive offer in the relationship with customers and in long-term loyalty?

They are a key part of our service. To this end, TDF has six workshops in Spain: Barcelona, Tarragona, Valencia, Madrid, Huelva and Bilbao.

At the same time, our stock of pumps and spare parts allows us to have very fast delivery times, as we have more than 10,000 m2 of warehouses dedicated to it in Spain.

What challenges and opportunities do you see for the coming years in the sector and how is the company preparing to face them?

The main challenges for the future will be digitalisation, the incorporation of AI, energy efficiency and security.

For TDF, in particular, we will continue with our internationalization process in Europe and Latin America, and we will continue to strengthen our human teams and modernize our products and services.

What does it mean for Técnica de Fluidos to be a Premium Partner of Expoquimia? What do you expect from your participation in the 2026 edition?

It means reinforcing our role as a benchmark in pumping and fluid transfer solutions in the chemical and process industry. The fair is a platform to showcase innovation, sustainability and efficiency, values that we fully share.

From our participation in 2026 we hope to consolidate relationships with customers and strategic partners, present our latest innovations in industrial pumping, highlighting energy efficiency and reliability, as well as generate business opportunities. In addition, we want to promote technology transfer, connecting with sectors such as fine chemicals, basic chemicals and pharmaceuticals.

A few months before the celebration of Expoquimia, can you tell us in broad strokes what the novelties you will present will consist of?

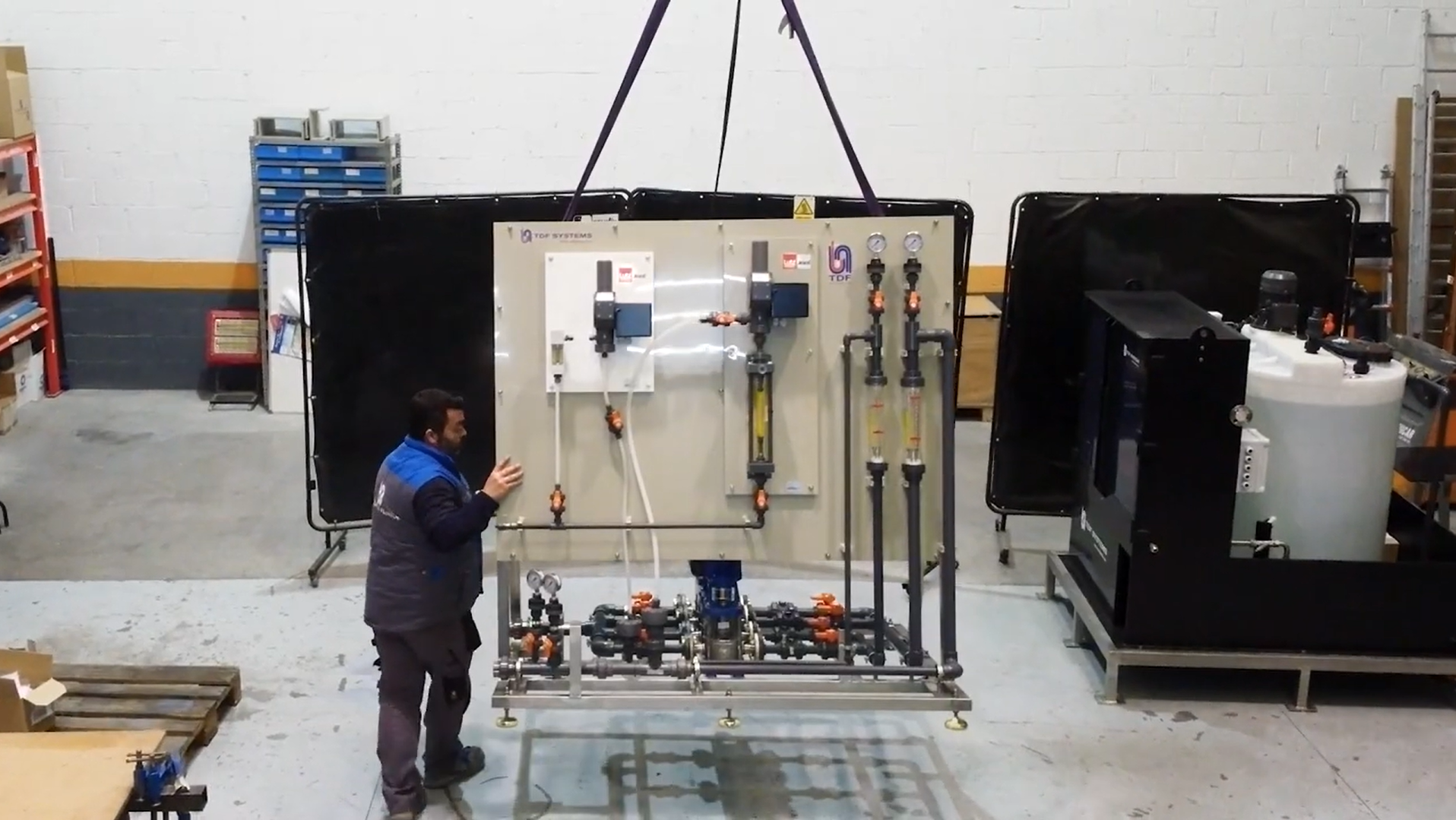

We are working on a very complete proposal. Our new products will focus, on the one hand, on Hygiaflex peristaltic pumps, ideal for processes where hygiene, exact dosing and resistance are critical, such as in pharmaceuticals, biotechnology and food; TDF Systems, aimed at optimizing processes and reducing operating costs; Wilden pneumatic pumps with ProFlo Shift technology, robust and reliable solutions for the process industry, where sustainability and savings are priorities; Boulton pumps, focused on the chemical and process sector, for applications where resistance to aggressive products and reliability are essential, and Sundyne pumps (HMD Krontro and Ansimag), an advanced technology for critical applications, with sealless designs that guarantee maximum safety, zero leakage and high efficiency in chemical and pharmaceutical environments.

On the other hand, we will make use of our experience in the green hydrogen sector, in which we have specific equipment to meet the needs of this emerging industry, offering safe and efficient solutions for critical processes related to the production and handling of hydrogen.

We will also present solutions for the lithium and battery sector, with equipment adapted for fluid handling in battery manufacturing and lithium treatment processes, where chemical compatibility is essential.

All these innovations respond to the demand for efficiency, sustainability and reliability that characterises the sectors present at Expoquimia.

Why should professionals in the sector visit this fair?

Expoquimia is not just a fair, it is the epicenter where the chemical and process industry reinvents itself. Professionals who attend will find applied innovation, as it is not just about seeing products, but about discovering real solutions to challenges such as energy efficiency, sustainability and digitalization.

They will also be able to establish a direct connection with manufacturers and experts, in a space to solve technical doubts, compare technologies and generate strategic alliances, as well as detect trends that will mark the future: from smart pumps to integrated systems for critical processes, all in one place. Finally, a fundamental part is practical experience: live demonstrations, success stories and opportunities to touch the technology that will transform the industry.

In short, it is the opportunity to anticipate what is coming and bring concrete solutions to your plant or process.