Interview with Àlex Ribé Bachiller, Head of the Bachiller Test Centre

Bachiller, founded in 1971 as a small workshop, is today a leading industrial engineering company in the design and manufacture of process equipment and pressure vessels for the chemical, petrochemical, pharmaceutical, cosmetics and food industries. Based in Parets del Vallès (Barcelona), it has two large production sites and a state-of-the-art Test Centre inaugurated in 2024. Once again, it will be a Global Partner of Expoquimia in 2026.

What are the key factors behind becoming a benchmark in Spain and in over 35 other countries?

I would highlight our commitment to in-house engineering and manufacturing. From the outset we were clear that we wanted full control over design and production. This has allowed us to offer highly customised solutions, adapted to international regulations and to sectors with very demanding requirements, such as pharmaceuticals and fine chemicals.

In addition, we have always strived to go a step further when it comes to technology. A good example of this is the Test Centre, which enables us to validate processes with clients and also strengthens our role as a technical partner, not just as a manufacturer. All of this has helped us differentiate ourselves and build long-term relationships based on technical trust.

Which are your most important markets?

Our main markets are in the European Union, where we have had a solid presence for many years and stable relationships with clients who are familiar with our technology.

At the same time, we are making firm progress in entering the US market, which is highly technical, competitive and demanding. We are already carrying out projects there with good results, which encourages us to continue growing in that direction.

In all these markets we work with companies that seek robust equipment, built to high quality standards, designed under regulations such as GMP and ASME, with clear requirements in terms of traceability, automation and process validation. This is precisely where we can add the most value.

One of Bachiller’s most recent milestones has been the commissioning of its new Test Centre facilities just a few months ago. What would you highlight about this testing laboratory?

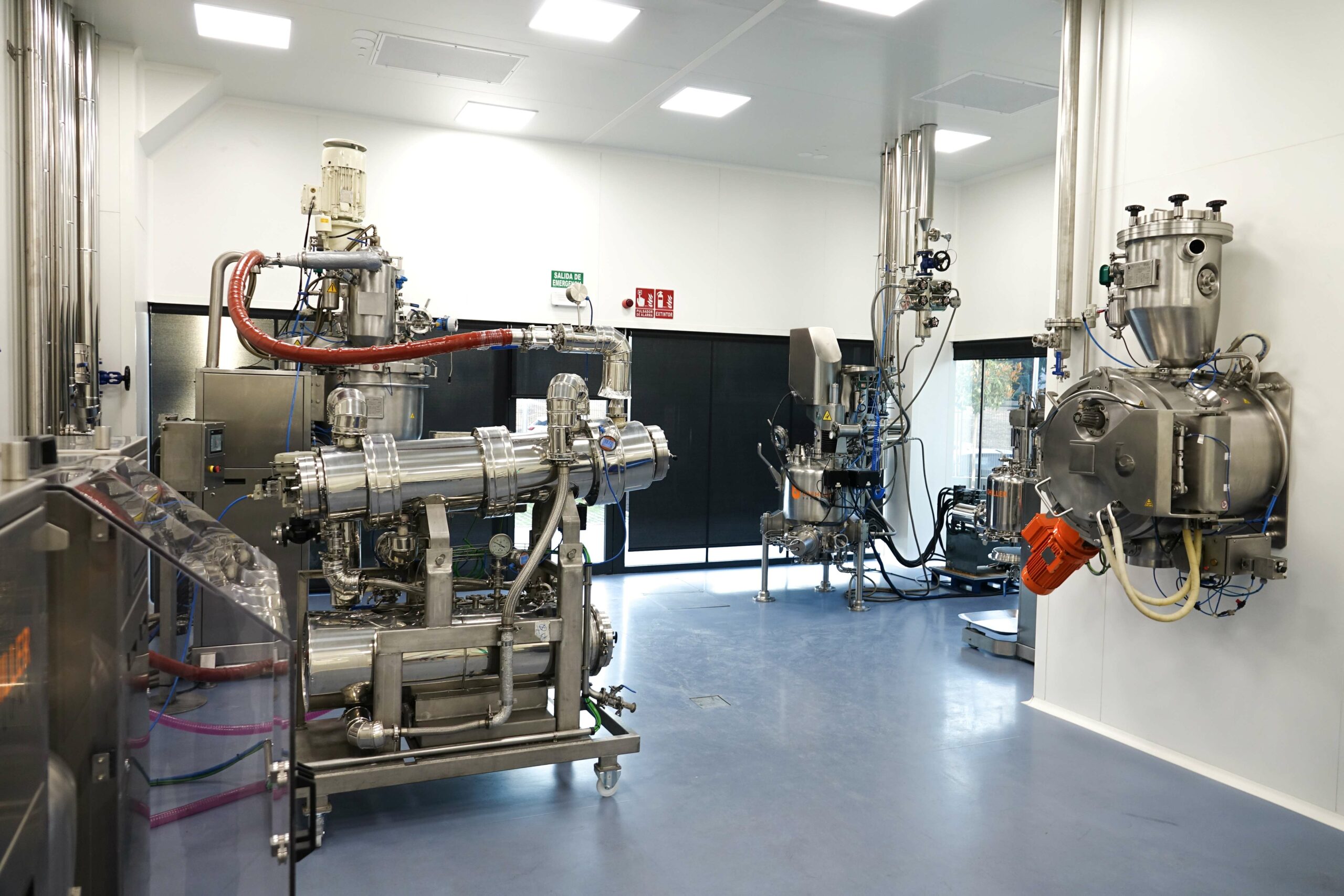

The Test Centre is conceived as a practical extension of our engineering capabilities. It is not just a laboratory: it is a space where real processes can be simulated under controlled conditions, very similar to those found in a production plant.

We have a wide range of pilot equipment that allows us to carry out many different types of tests. The interesting part is that it is not only about checking whether something works, but also about adjusting parameters, testing different configurations and technically validating the process before taking it to industrial scale.

How can the Test Centre help your clients?

It allows them to test the feasibility of their processes, develop new formulations or even validate equipment before investing in a definitive industrial solution. Our specialists prepare and carry out the trials in a controlled environment, carefully documenting all process data, although clients are welcome to attend in person if they wish.

What we really aim for at the Test Centre is to obtain real, verifiable data that help decision-making and support choosing the most efficient option. At the end of each test, the client receives a full technical report with all parameters, results and our recommendations for scaling up the process safely.

And of course, everything is carried out with maximum confidentiality. If required, we have an NDA model ready to be signed before starting any trial. This is something we take very seriously.

Behind this project there must be a strong team. Which are the main departments involved and what role do they play?

We work in close coordination across several departments. On one side, the commercial team plays a key role: it supports the client throughout the entire process, from planning the test to interpreting the results, acting as the link between the client and Bachiller’s technical teams.

On the other side, the team of engineers at the Test Centre, of which I am part as head, is responsible for preparing and executing the trials, ensuring everything is carried out under controlled conditions and with maximum technical rigour.

The third pillar is the Technical Office and the R&D&I department. Very often, what we learn during a test not only helps validate a client’s process, but also provides us with insights to improve our own designs. This constant connection between real trials and development allows us to evolve towards more efficient equipment tailored to market needs.

What is Bachiller’s sustainability strategy based on, and what are the main measures the company has implemented in this area?

At Bachiller we are committed to real, applied sustainability – not just as a trend, but as part of our business strategy. We are aligned with the Sustainable Development Goals and have already succeeded in reducing our carbon footprint by 20%.

In addition, we hold ISO 9001 and ISO 14001 certifications, and we have recently been awarded the bronze medal by Ecovadis. All of this is part of our quality and environmental policy, which we continue to reinforce on a daily basis.

What does being a Global Partner of Expoquimia mean for Bachiller?

For us it is a great opportunity. It is not just about being present at another trade fair, but about working closely with one of Europe’s most renowned chemical sector events. This partnership enables us to strengthen our positioning and gain very significant visibility both nationally and internationally.

What expectations do you have for the 2026 edition?

Our expectations are high: we want to present our latest technical solutions, representing our main product lines: vacuum drying, filtration and mixing of solids, liquids and semi-solids. We also hope to generate new business opportunities and continue building strong relationships with clients and technology partners.

What can companies in the sector gain from visiting this trade fair?

I have been attending Expoquimia for many years, and it has always been a must-attend event. It is not just a trade fair, but the meeting point of the chemical industry. It allows you to see first-hand where technology is heading, what the industry is concerned about, and what solutions are being developed.

Moreover, it is a unique opportunity to see real equipment in operation, talk face to face with manufacturers, share experiences and create new connections. You always return with ideas, contacts and a much clearer vision of the market. For any company in the sector, being at Expoquimia means being on the map.